What is Thermal Imaging?

Often referred to as infrared imaging, thermal scanning or thermography, thermal imaging is a technique used to see the infrared section of the light range.

On the left is the Cummins diesel aquatic engine being operated during a sea trial. The image on the right is a Thermal MSX® photo.

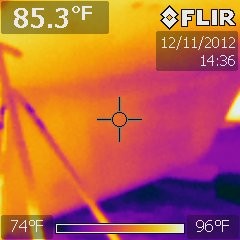

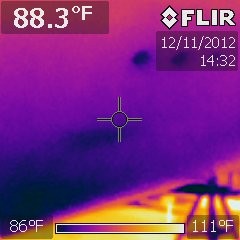

The image on the left is a hull thermal image whereas the ideal photo is a Thermal MSX® photo.

As you can see from these images, MSX® technology in FLIR® electronic camera offers a clearer image that enables the surveyor to easily spot possible issues.

What Does This Mean to Me? How Does it Assist?

Thermal imaging makes it easy for marine surveyors to identify potential issues which may otherwise be missed when using traditional surveying techniques and tools. As you may already know, marine surveys use ‘non harmful’ techniques. This means components are not dismantled to look inside. A qualified surveyor simply observes and listens to determine if a component has an issue. Consequently, without taking components apart, it can be hard to find such issues as misalignment or excess wear when examining such equipment as power steering pump, generator or electrical panels. If an issue cannot be seen using naked eyes, surveyors might not know if a problem exists. This is where the need for thermal scans comes in. Thermal imaging can help identify a possible issue such as warm exchangers for the engine cooling systems, or damaged bearings. All this can be seen without ever taking components apart. Thermal imaging can help identify coolant clog which may be harming the engine. This can be done without removing the component from the engine. For the electrical panels that power onboard electrical systems, thermal imaging can be used to spot potential problems which would otherwise only be determined by dismantling the panel and having a qualified electrician test out the parts. While we do not suggest you ignore the input of electrical or mechanical professionals, thermal scanning can identify serious issues before you buy a marine vessel.

Just How Does Thermal Imaging Work?

ETo understand how thermal imaging works, it is good to start by noting that everything releases some levels of thermal radiation. This is what enables thermal imaging to work when observing temperature abnormalities in electric devices, machinery and other solids such as fiberglass, wood, steel and lightweight aluminum. The unique thing about thermal imaging is that it doesn’t require light. The equipment uses thermal radiation to create an image. This means thermal cameras are able to see in complete darkness.

Thermal imaging is used in a number of industries for pre-failure examinations and maintenance of equipment. While it is somewhat a new technology in marine surveying, the technology has been around for years and is used extensively in the survey of aircraft hulls and other systems. At Sun Coast Marine Surveying, we are committed to making sure our surveyors have the best technology when rendering services to customers.

.

A thermographic camera is what is used in thermal imaging. The camera is similar in operation and appearance to a mobile electronic video camera. At Sun Coast Marine Surveying we use the FLIR® brand name infrared electronic cameras. We use the FLIR® cameras that use MSX® Thermal Image Enhancement. While the technology is readily available on the FLIR® brand of cameras, it is good to note that not all FLIR® electronic cameras use the MSX® technology. The good thing about the MSX® technology is that it adds more details to the infrared image using a light video camera in real-time. This leads to a more detailed thermal image that has labels, numbers and architectural functions. This makes it easy to identify a component and what is damaged.

1. Digital Image 2. Thermal Image 3. Thermal MSX

In thermal imaging, the infrared video camera has a special lens that concentrates infrared light that is emitted on the items in view. The MSX® electronic camera is equipped with additional lenses that record the electronic photo and then generates three photos. With the FLIR® software, you can view every image in three layouts: Thermal MSX, Thermal Image or Digital Image. A Thermal MSX image overlays an electronic photo over a thermal image so as to create an image that is clear and easier to identify

Does Thermal Imaging have Advantages?

Thermal imaging has many advantages. When used in marine survey, the imaging technique offers the following key benefits:

- There is no need to touch the components being assessed. The surveyor is able to diagnose components without touching them. This means they can assess moving and extremely hot parts of the engine. A surveyor can also analyze a high voltage electric component without the risk of being electrocuted.

- Everything is done in real time. After scanning, you don’t have to wait for the images to be developed. The real-time imagining permits fast scanning and recording of stationary and moving targets.

- You can clearly see thermal patterns. Being able to see thermal patterns helps save money and time that would otherwise have been spent hiring a technician to tear components apart. There is also no need to comb through miles of wires to locate a problem on a luxury yacht or watercraft. Thermal imaging helps find temperature anomaly fast.

- BBoosts details in a survey report. We offer thermal scanning at no extra cost. Thermal imaging helps identify leaks, malfunction or delamination on elements like transmissions, electric systems, hulls, decks, electrical tools and engines. This information is vital when buying a pre-owned boat.

Thermography And How It Makes a Boat Safer

Thermography increases the safety of a boat and helps you know if you are making a good investment. Thermography helps identify heat that might lead to fires thus helping you avoid electric fires. Thermal scanning is also effective in spotting fuel and water leaks from tanks thus helping you avoid explosions or water damages to the boat. Thermal imaging is also used to identify temperature abnormalities in the transmission or engine. This helps prevent costly transmission or engine repairs.

The photos on the right show problems of delamination that were detected using thermal imaging. Thermal cameras in marine surveys help qualified marine surveyors recognize potential structural problems which could easily be missed when using standard survey methods.

While thermal imaging is quickly changing the way marine surveyors work, surveyors still use the tried and tested survey techniques that have been around for years. At Sun Coast Marine, our team still uses traditional survey techniques such as percussion soundings and GRP33 wetness meters. We, however, use modern technology to get more details. Our go-to equipment is the FLIR® thermal video cam that is equipped with MSX® imaging technology. Keeping up with new technologies is what sets us apart from our competitors.

Thermal image of a onboard generator operating under a load.

Thermal image of a Cummins Diesel engine

Infrared thermal image of hull delamination on the lower right side of the image.

Infrared thermal image of a hull bottom with hidden delamination under the fiberglass